Research Overview

Check out this extended version of Rachel's interview with the UCSB College of Engineering:

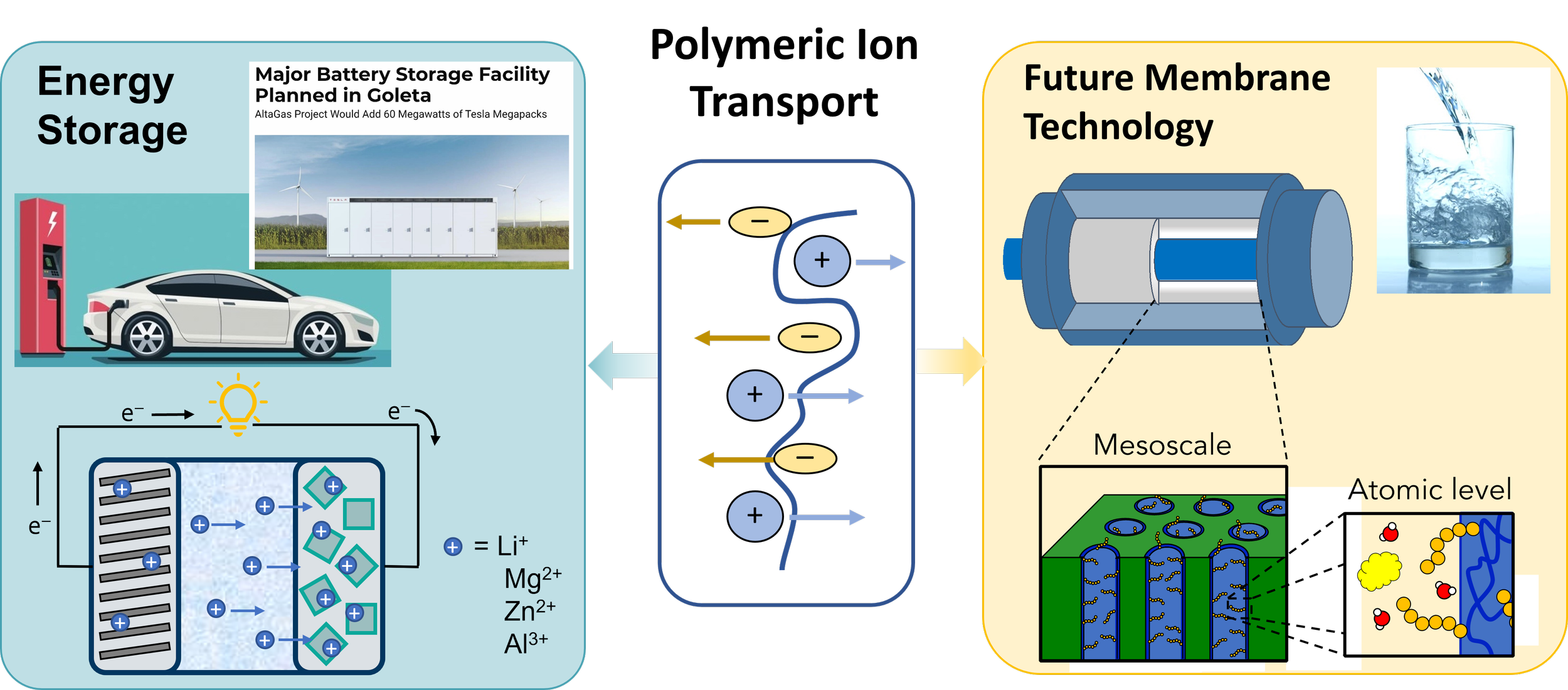

The Segalman group answers fundamental polymer physics questions at the heart of energy and sustainability. We are particularly interested in the fundamental interactions that lead a polymer to "fold" like a protein as well as the interactions between a polymer and an ion that leads to ionic conductivity or highly selective separations for water purification. For this reason, we use molecular design and synthesis combined with measurements of materials properties to establish design rules for new materials for applications ranging from energy storage (batteries) to water separation, polymer upcycling, and marine anti-fouling.

While plastics hold great promise as inexpensive components in safe, flexible energy generation and storage devices as well as efficient water purification membranes, this promise is reliant on the ability to design materials with selective transport of ions, electrons, and/or heat. The Segalman group has works to understand the relationship between molecular design, thermodynamic assembly, and processing to dictate morphology and desired physical properties. This has resulted in new molecular designs for superionic conductors, mixed ion/electron conductors, semiconducting polymers with controllable melting and liquid crystalline transition temperatures, as well as deep understanding of how to control the assembly of ionically conductive polymeric ionic liquids and bio-inspired poly(peptoids).

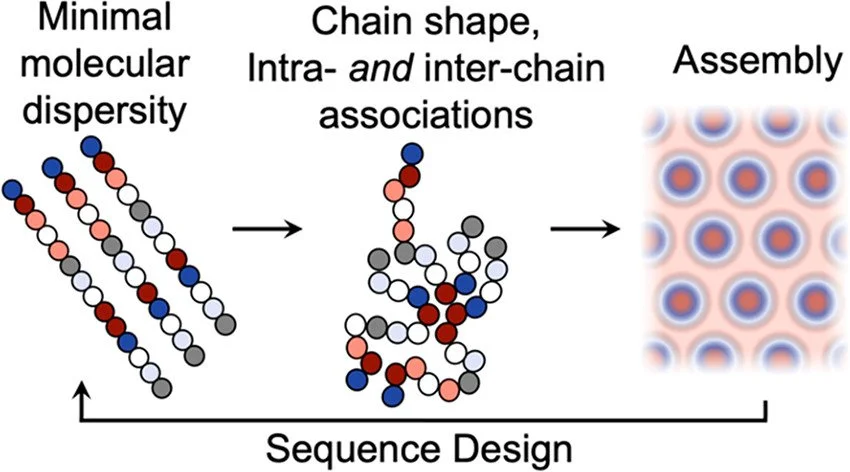

Polypeptoids are a versatile platform that allow sequence control on the monomer level. This enables us to answer fundamental polymer physics questions including the effects of chain shape in polymer melts, self-assembly of block copolymers, and hydrophobic sequence patterning on chain collapse and assembly in solution.

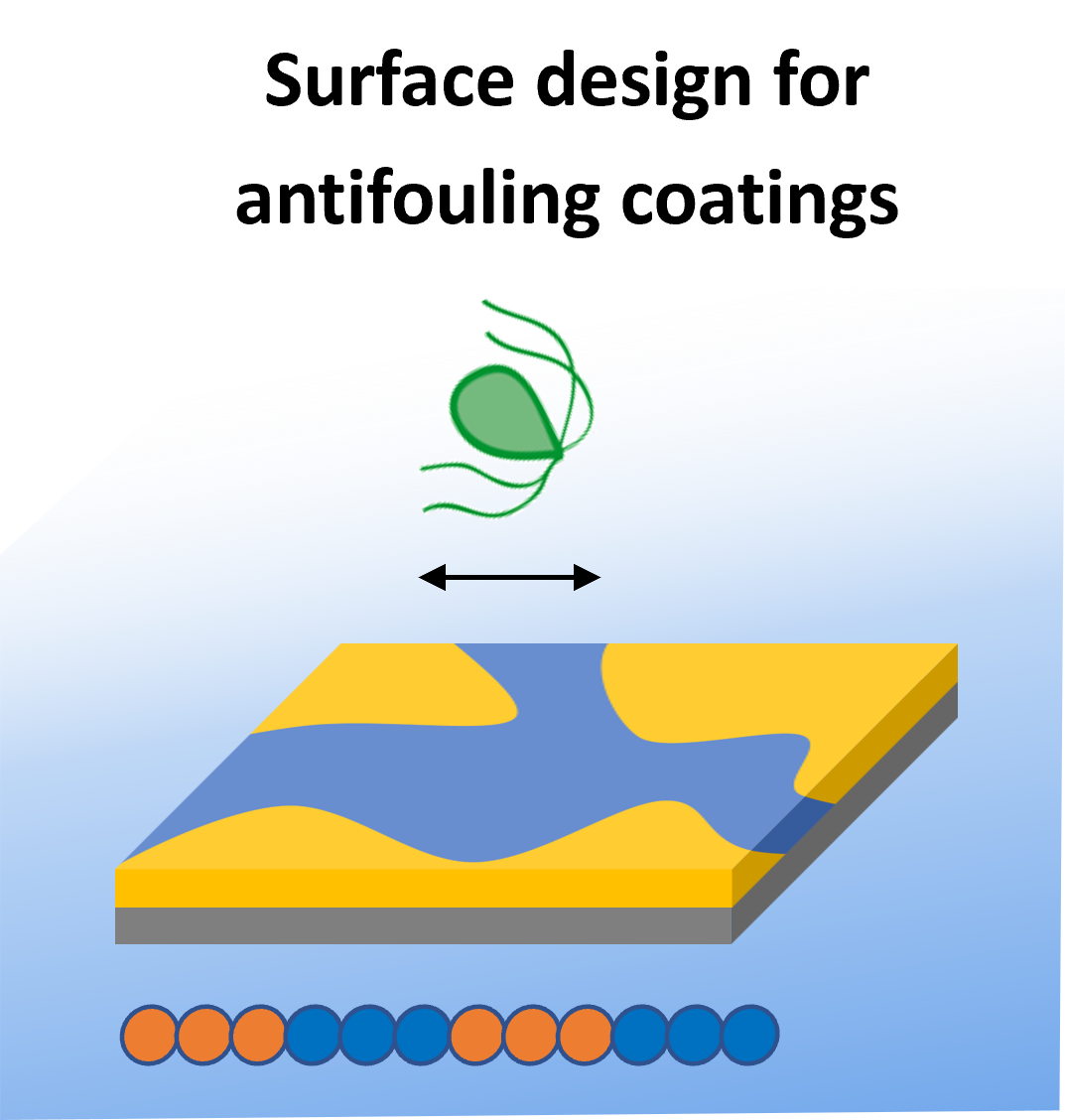

Insights from our fundamental sequence-defined self-assembly can have important implications for a variety of applications, including antifouling coatings, which can reduce biofilm accumulation and dramatically improve the energy efficiency of ships.